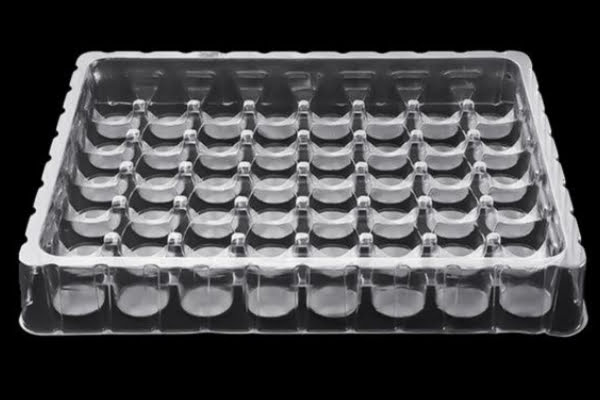

Plastic Packaging Trays

Plastic Packaging Trays

Over 30 Years of Experience, Abhinav Enterprises has become a reputed Plastic Packaging Supplier, Blister Packaging Manufacturer and Supplier in Delhi, NCR, India. Plastic Packaging Trays Blister Packaging is manufactured with high-quality PVC / Plastic packaging material and goes through for quality check before packaging. With our experience, the latest machinery, and infrastructure, We can customize the products as per the customers’ needs. We are supplying Blister Packaging for Food Items in Delhi, Noida, Greater Noida, Gurugram, Ghaziabad, Jaipur, Bhiwadi, Sonipat, Ahmedabad, Bhopal, Lucknow, Patna, Raipur, Chandigarh, North India, and Rest India.

Plastic Packaging Trays: A Versatile and Reliable Solution

Plastic packaging trays are a popular choice for organizing, protecting, and displaying products in industries such as food, pharmaceuticals, electronics, and consumer goods. Their durability, customizability, and cost-effectiveness make them an ideal packaging solution. Here’s why plastic packaging trays are widely used:

1. Durability and Protection

- High-Impact Resistance: Plastic trays are designed to withstand rough handling, ensuring products remain safe during transit and storage.

- Crush Resistance: The rigid structure of plastic trays protects fragile items from damage.

2. Customizable Design

- Multi-Compartment Options: Plastic trays can be designed with multiple compartments to organize and separate products, such as electronic components or medical devices.

- Custom Shapes and Sizes: Trays can be tailored to fit specific products, ensuring a secure and snug fit.

3. Hygienic and Food-Safe

- Food-Grade Materials: Plastic trays made from food-safe materials like PP (Polypropylene) or PET (Polyethylene Terephthalate) are ideal for packaging fresh produce, meats, and baked goods.

- Easy to Clean: Plastic trays are easy to sanitize, making them suitable for reusable applications in the food and pharmaceutical industries.

4. Cost-Effective Solution

- Affordable Production: Plastic trays are cost-effective to manufacture, especially when produced in large quantities.

- Automated Manufacturing: Injection molding and thermoforming processes allow for high-volume production with minimal labor costs.

5. Eco-Friendly Options

- Recyclable Materials: Many plastic trays are made from recyclable plastics like PET, PP, or HDPE (High-Density Polyethylene), reducing environmental impact.

- Biodegradable Alternatives: Some manufacturers offer trays made from biodegradable materials like PLA (Polylactic Acid) for eco-conscious brands.

6. Versatility Across Industries

- Food Industry: Used for packaging fresh produce, meats, seafood, and ready-to-eat meals.

- Pharmaceuticals: Ideal for organizing pills, syringes, and medical devices.

- Electronics: Protects and organizes small components like circuit boards and connectors.

- Consumer Goods: Used for packaging cosmetics, hardware, and toys.

7. Enhanced Product Presentation

- Transparent Trays: Clear plastic trays allow customers to see the product, enhancing its visual appeal.

- Branding Opportunities: Trays can be customized with logos, colors, and product information to strengthen brand identity.

8. Lightweight and Stackable

- Easy to Transport: Plastic trays are lightweight, reducing shipping costs and making them easy to handle.

- Stackable Design: Trays can be stacked efficiently, saving space during storage and transportation.

9. Sustainability and Innovation

- Reduced Material Usage: Advanced manufacturing techniques minimize material waste during production.

- Smart Packaging: Some plastic trays incorporate RFID tags or QR codes for tracking and inventory management.

Conclusion

Plastic packaging trays are a durable, cost-effective, and versatile solution for organizing, protecting, and displaying products across various industries. Their ability to provide customizable, hygienic, and eco-friendly packaging makes them a top choice for businesses. Whether for food, pharmaceuticals, electronics, or consumer goods, plastic trays ensure product safety, convenience, and enhanced presentation.